Clicking or Beeping Hard Drive

The cause for concern

It’s never a good sign if your drive starts to make odd clicking, beeping or worse still scraping noises. If this is the case stop using the drive immediately, you could be damaging data every second the drive is powered on.

The first question we ask about a drive is was it exposed to physical damage – was it dropped. It’s a very important question that dictates the way we conduct our evaluation. We don’t open the top cover of drives unless we need to, however careful we are it exposes the data to additional risk we like to avoid. The exception to this are drives which have suffered physical damage. Before applying power to a drive we suspect has physical problems we conduct a full internal examination of the drive and it’s head stack assembly under a microscope, we can then see if powering the drive would cause damage.

Inside some clicking drives

Platter Damage

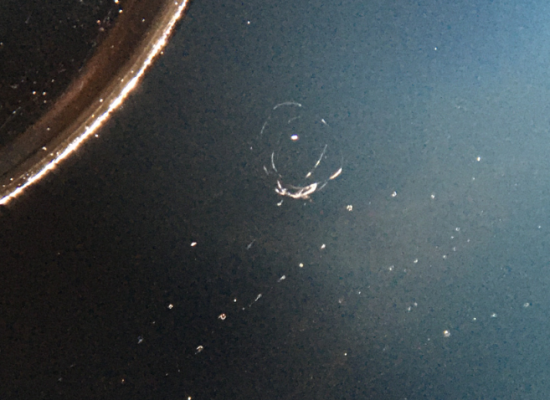

Fig 1 : This ST2000VM003 a 2TB Seagete Pipeline was sent to us clicking having had a “knock”. Unfortunately a local repair company had already tried unsuccessfully to copy the data.

The data surface, known as the platter should be completely clean. Clearly visible on the left hand side of the image is a deep gouge where the head has “crashed” into the top surface. The rest of the platter which should have an absolutely mirror finish resembles Saturn’s rings where the head has been scrapped across a significant number of times causing more damage.. The orange parking ramp and the heads themselves are covered in the fine dust created by the sanding of the platter surface.

We didn’t get to this one in time and unfortunately the fine dust was all that was left of the data.

Head Damage

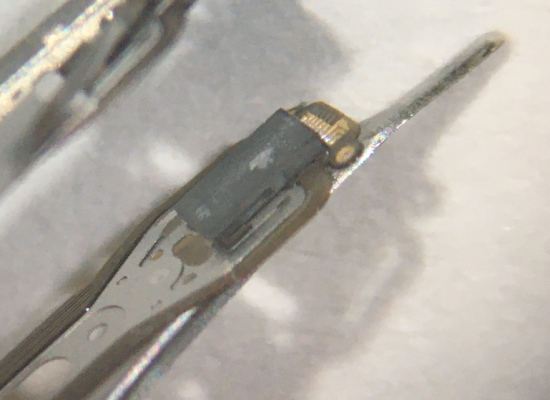

Fig 2 : These heads belong to a Seagate 1TB 2.5″ Drive, ST1000LM014 and shouldn’t look like this. When parked the heads should be in line with the actuator arms. These heads had caught on the parking ramp and been ripped out of position. The customer reported the drive clicked when powered on but stopped immediately and powered down after a few seconds before sending the drive to us.

Fig 3: From the same drive above but showing a view of the damage to the platters. This image was again taken using a microscope at 20x . Where the head has caught the surfaces and then twisted can be seen. Leaving circular scratches in the surface of the platters. There are also signs of several nicks the head has left as it bounced on the surface.

Head Contamination

Fig 4 : This can be overlooked even by a professional recovery service, causing the head stack assemble to be replaced when not really needed. At 20 X magnification under the microscope you can see the dust contamination on the head. There was a small area of damage on the outside of the platter which had created the dust. This was very carefully cleaned and then reassembled in the drive. Although the drive speed was less than normal we saved the customer the cost of a donor drive and a head assembly swap..